Responsible Supply Chain

Realizing our comprehensive sustainability commitments requires close collaboration among all our employees and business partners. Zyxel outlines clear short- and long-term plans to ensure the seamless implementation of our initiatives for a truly sustainable value chain.

Zyxel products disclose conflict mineral sources

100% of Zyxel's key suppliers have achieved ISO 14064-1 certification

Our supplier management

Qualification

Require new and existing suppliers to follow the requirements and sign the Statement of Supplier Code of Conduct.

Risk management

Ensure suppliers maintain righteous and efficient operations through regular audits and on-going education.

Conflict mineral management

Conduct annual surveys to ensure materials and components of Zyxel products come from responsible sources.

Supplier qualification

We announce our "Supplier Code of Conduct" and "Conflict Minerals Statement" as a clear demonstration of our dedication to fostering a responsible supply chain. The "Supplier Code of Conduct" encompasses six key sectors, including:

These sectors collectively align with globally recognized sustainability standards.

Supplier audits

We categorize suppliers based on annual transaction volumes and require all key suppliers to undergo audits on criteria following principles and guidelines of the RBA Validated Audit Process (VAP). We adopt digital and onsite audit methods and issue audit reports to suppliers. For those identified as unqualified, we provide assistance in developing improvement plans. We completed a 100% supplier audit through onsite and digital methods, with all audited suppliers qualified.

Supplier risk management

Based on our supply chain risk assessment and management framework, we categorize supply chain risks into three sectors – economics, society, and environment. Zyxel encourages its suppliers to actively pursue related certifications and mitigate potential threats to healthy operations.

Zyxel key supplier certification achievement rate

| Economics | Society | Environment |

|---|---|---|

|

ISO 9001 TL9000 TL 9000 R6.0 |

RBA EcoVadis CDP or equivalents |

ISO 14001 |

| 100% | ||

Response to the pandemic

In response to the supply chain challenges caused by the COVID pandemic, Zyxel has taken practical measures to minimize negative impacts on business operations, including portfolio diversification, effective raw materials, and components stock management.

Our conflict mineral management

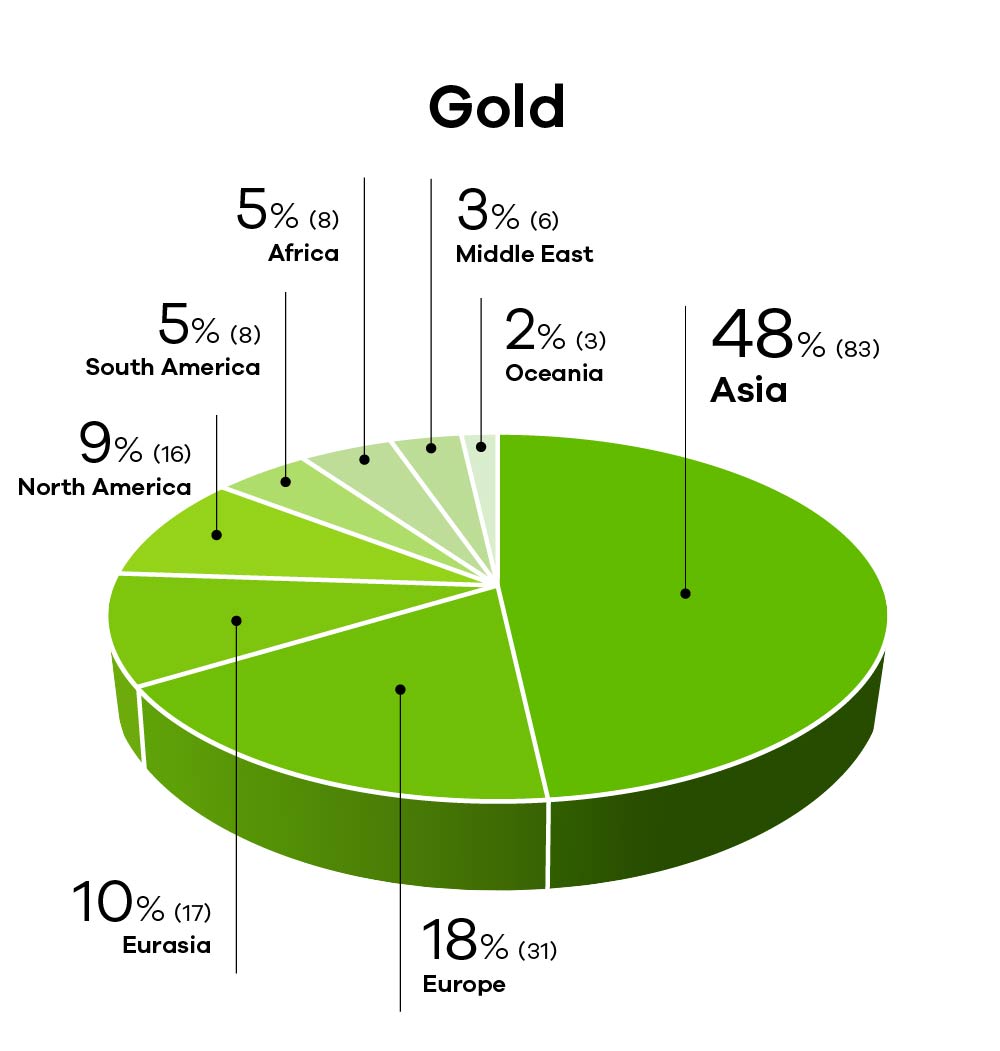

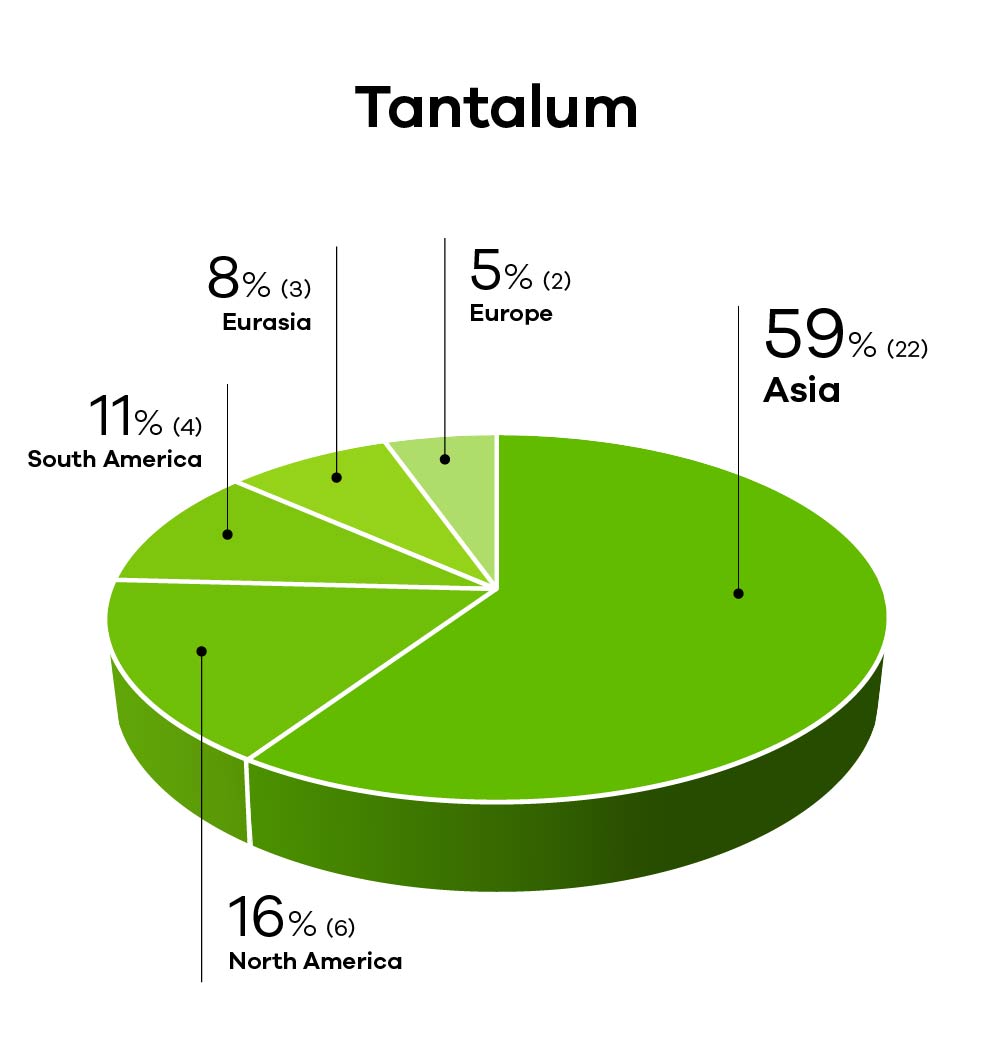

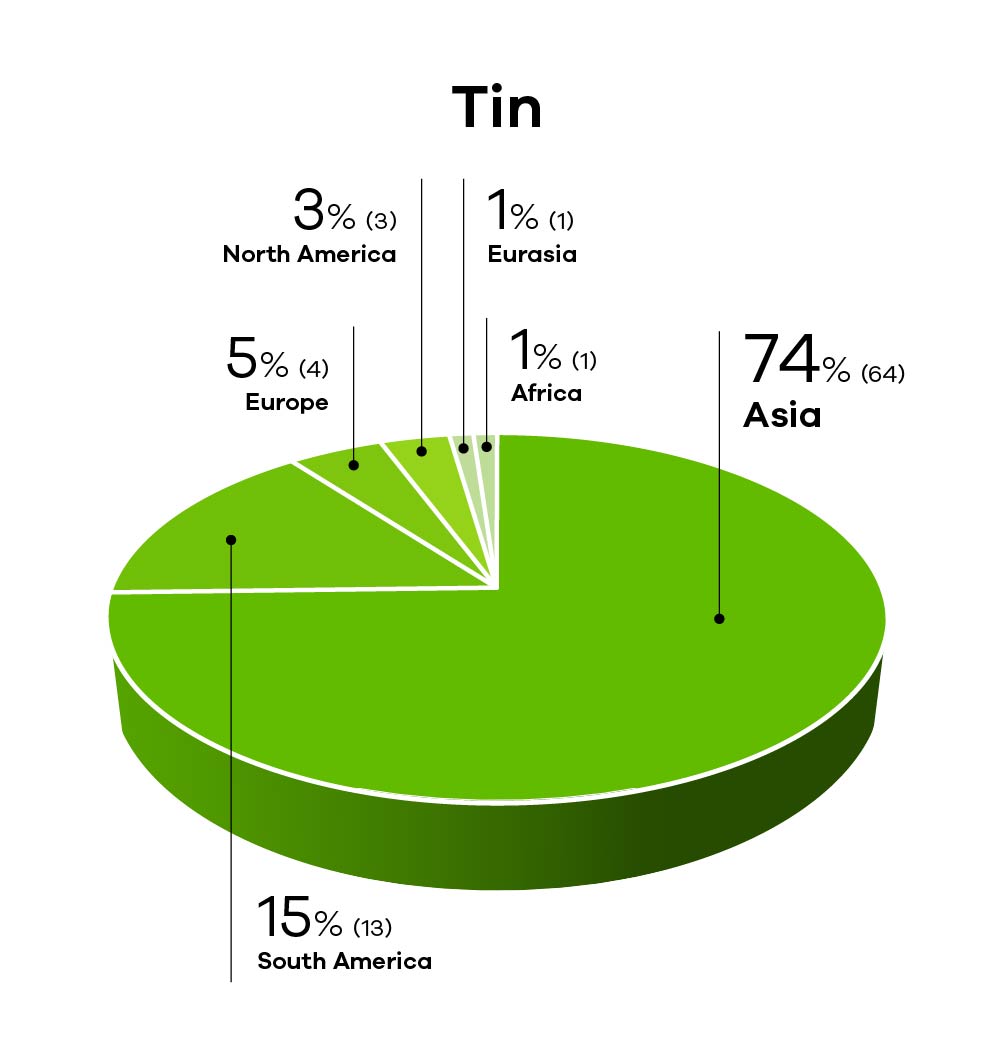

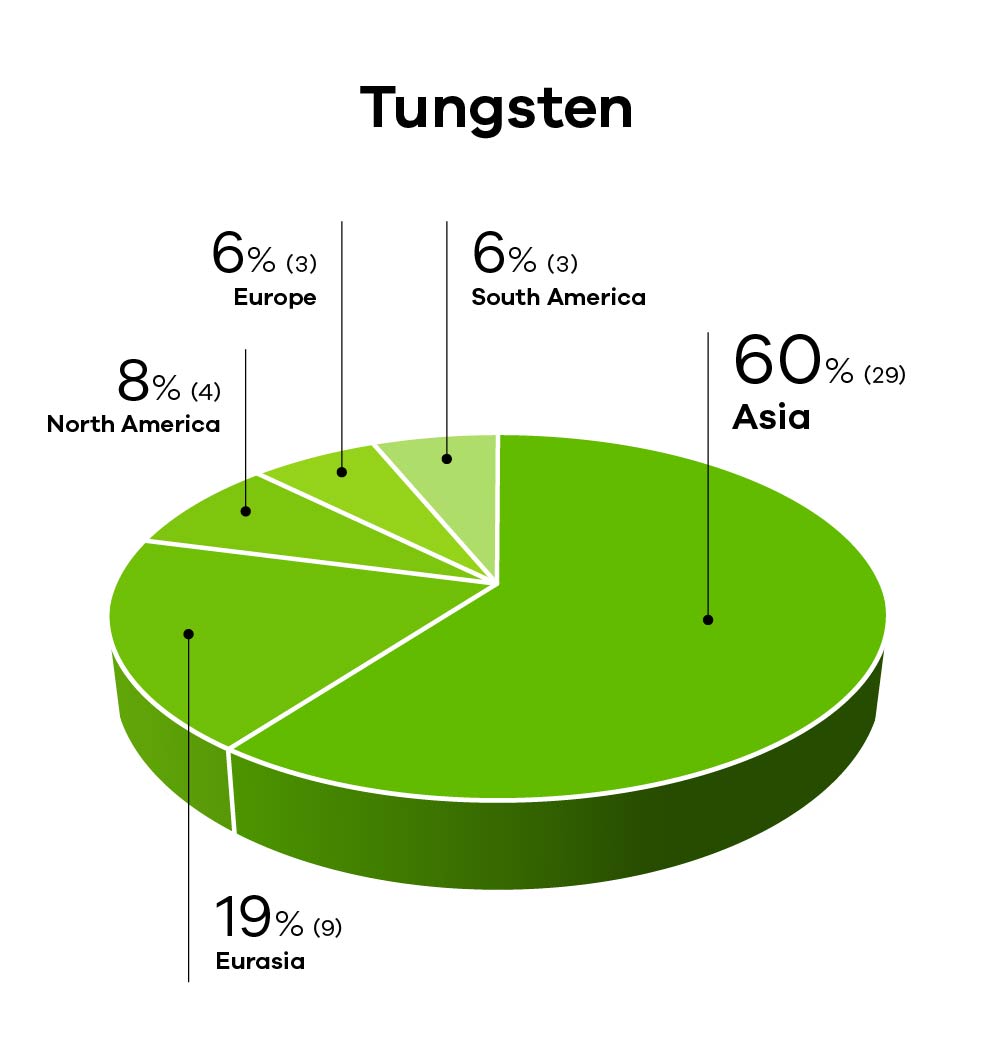

Aiming to help stem the trade in four minerals – tin, tantalum, tungsten, and gold (3TG) – that finance armed conflicts or are mined using forced labor, Zyxel performs comprehensive due diligence within the supply chain to ensure the above minerals are not derived or sourced from mines in conflict areas of the Democratic Republic of Congo (DRC) or illegally taxed on trade routes, either of which is controlled by non-governmental military groups or unlawful military factions.

Annual Mineral Source Survey

As a global corporate citizen, Zyxel fulfills its social responsibility for human rights and environmental protection. We commits not use conflict minerals, and follow the requirement of the Responsible Minerals Initiative and Organization for Economic Cooperation and Development (OECD) "Guidelines for Due Diligence of Mineral Supply Chains in Conflict-Affected and High-Risk Areas", implement regular due diligence to require all suppliers to disclose the use of smelters relevant information by using the latest Conflict Minerals Reporting Template (CMRT) for Gold, Tin, Tungsten, Tantalum and Extended Minerals Reporting Template (EMRT) for Cobalt and Mica.

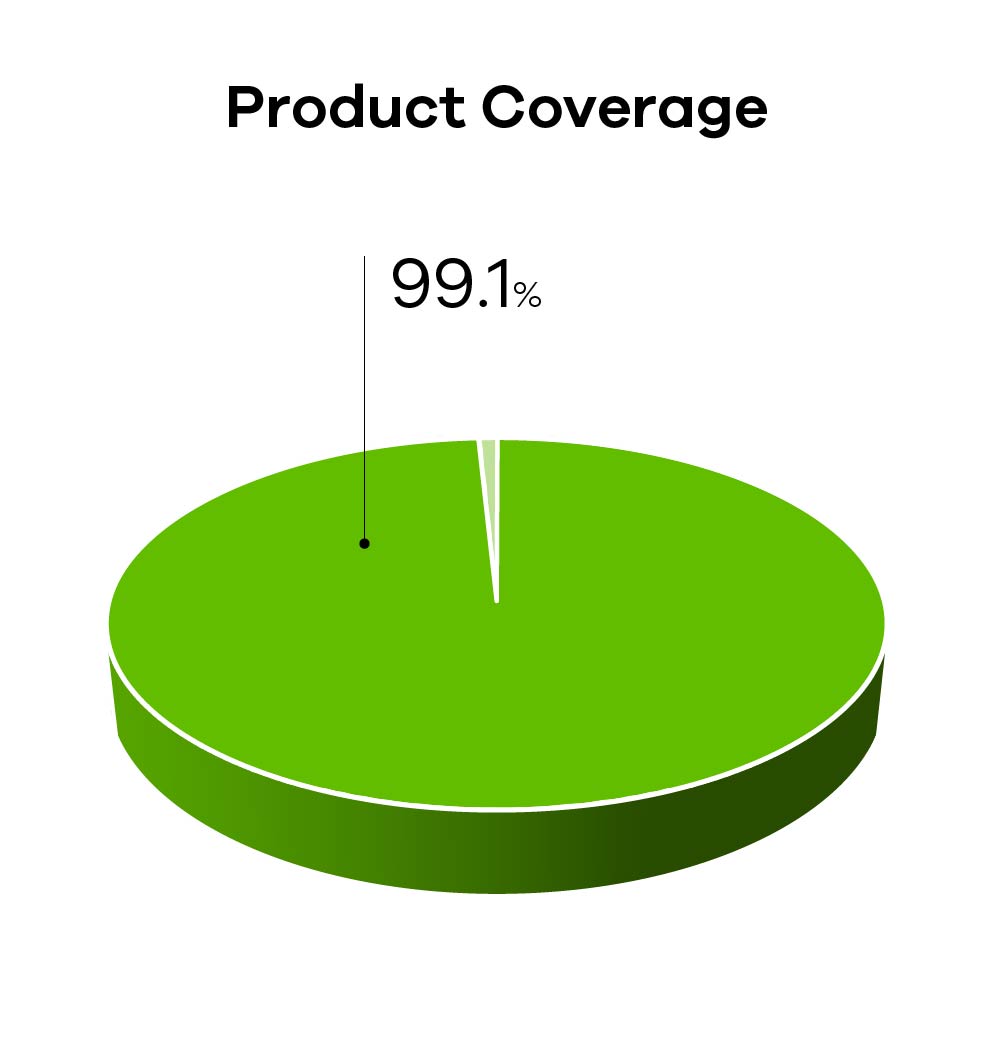

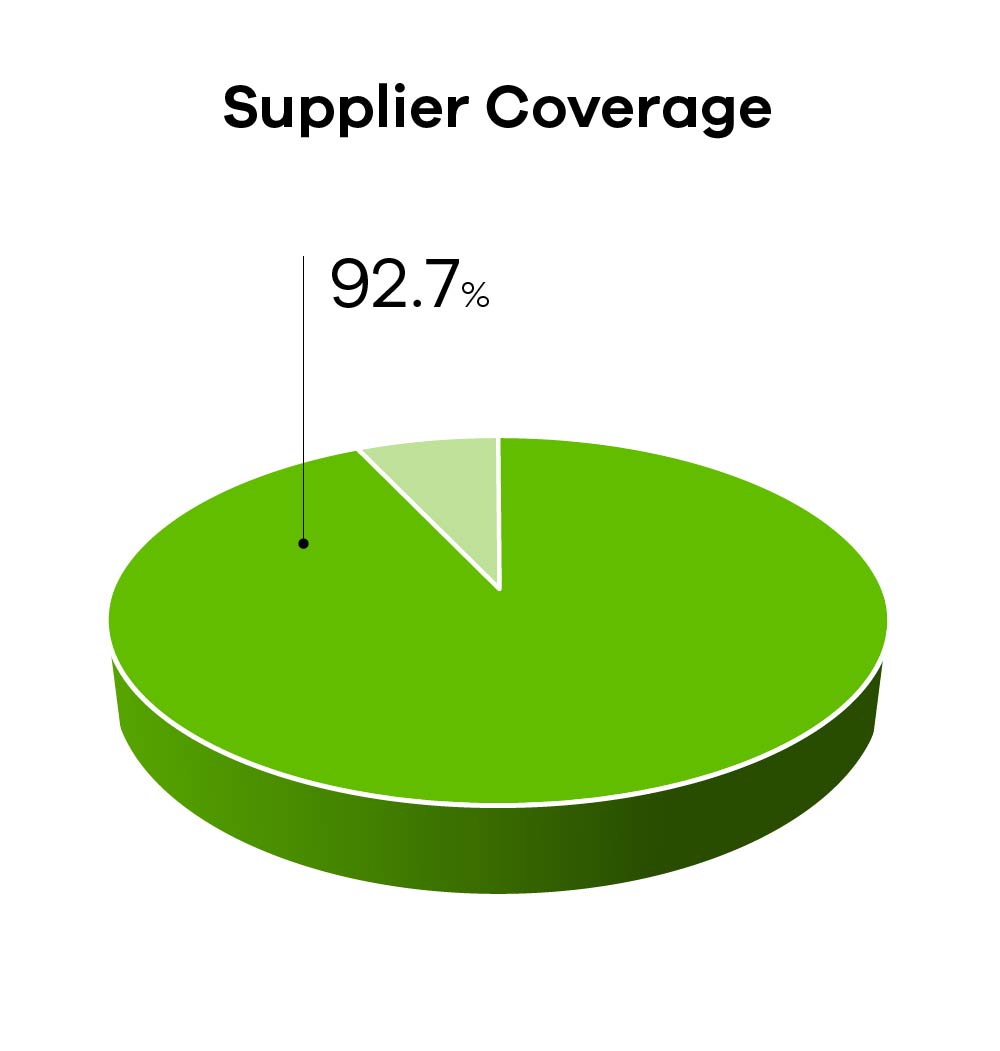

Zyxel conduct annual survey of conflict mineral source on product and supplier, survey coverage % are as follows.

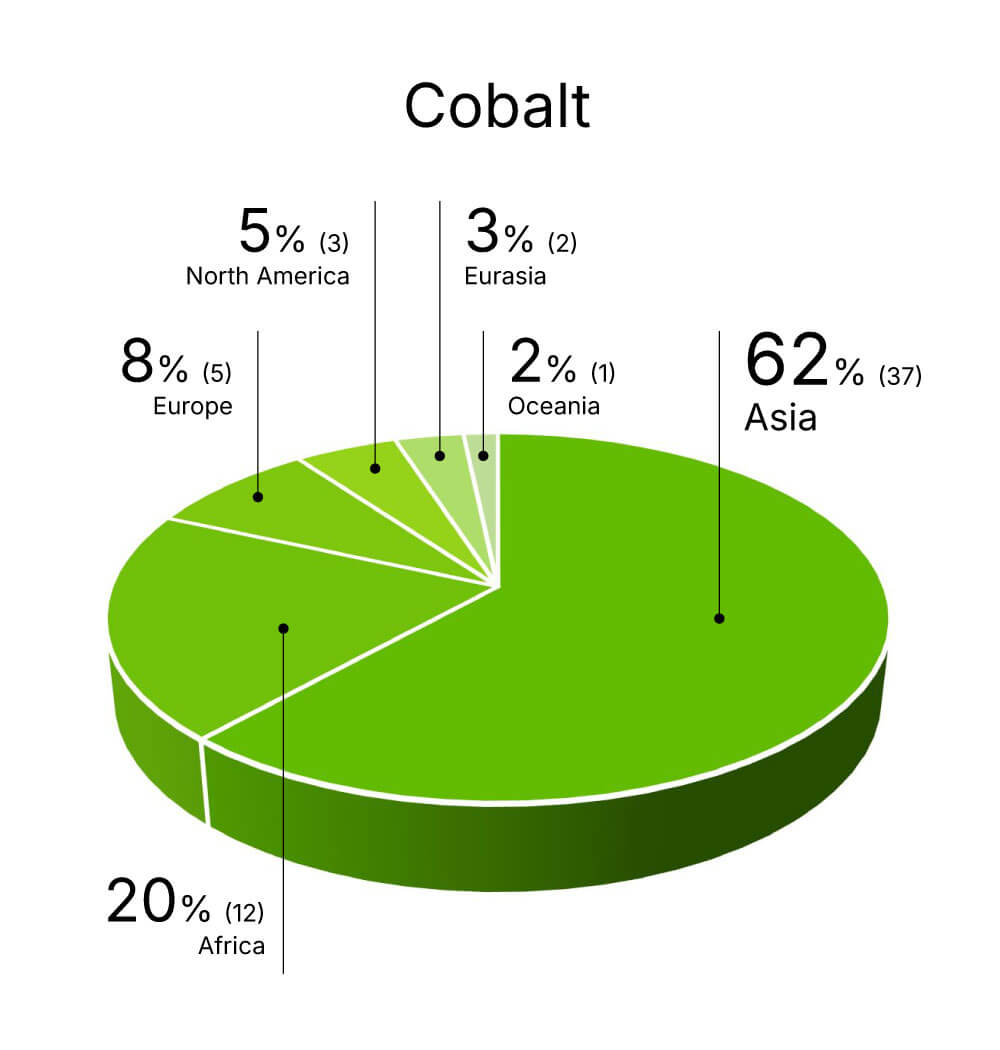

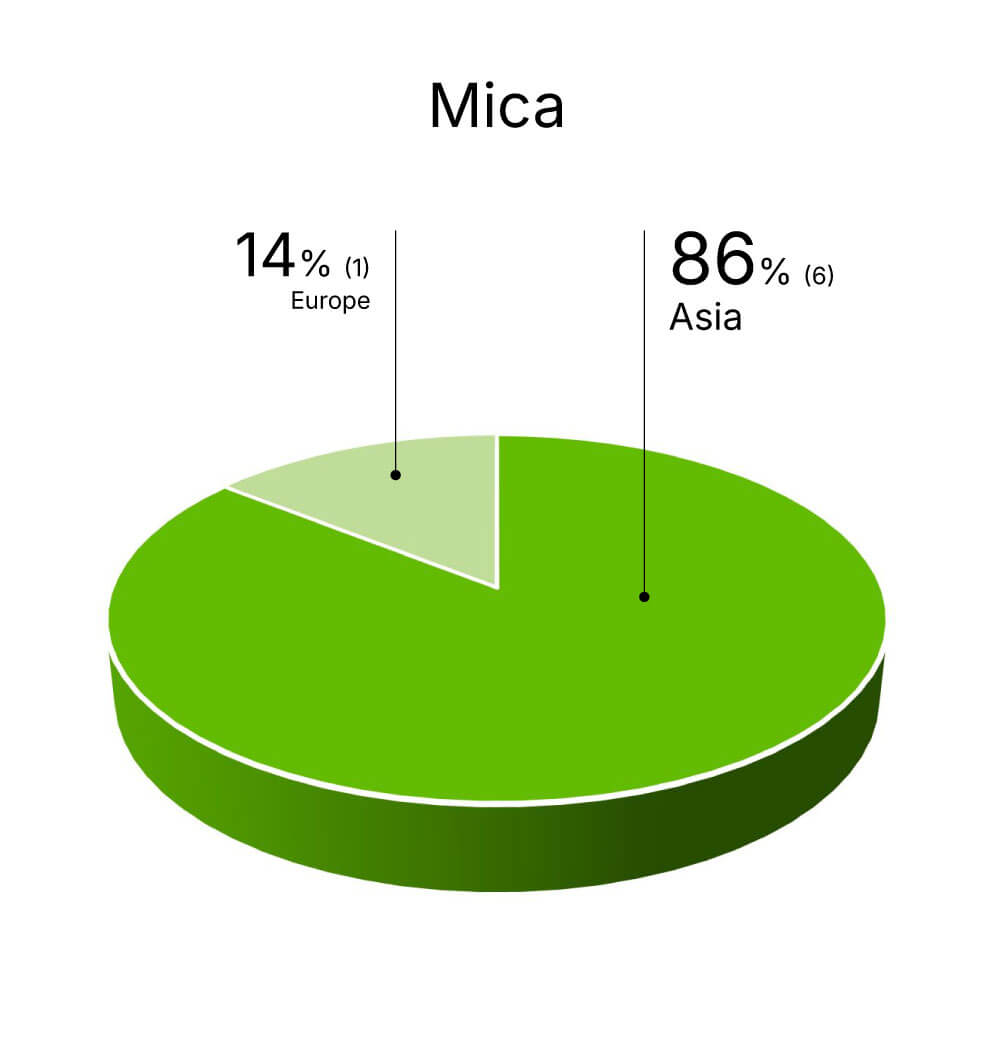

For 2024, Distribution area and numbers of qualified smelters listed in the following.